Clean, clear water. How important that is. So much so, that millions of people purchase bottled water on the premise that it is cleaner than the tap water in their own homes to drink. When we think about building a home in space, on the Moon, or Mars we’re going to need that water.

In space it is nearly non-existent, on the Moon and Mars it is locked up in ice either in deep, dark, craters or beneath CO2 ice in glaciers. As such it will be expensive in energy, and labor to mine from those locations. And once it is acquired, it will have to be purified to assure it is fit to drink. Even then, we will not wish to waste it. The water we use will need to be recycled to maintain our supply, despite evaporation, and some leakage from the habitat.

There are several ways to filter water. One method that is used in pond filtration is a biological filter. Also in slow sand filters, the slime that develops on the top of the sand filter is a biological filter. These work best when there is a large surface area for “good” bacteria to reside, and then water flowing and interacting with those surfaces allows the bacteria to attack, and or consume pathogens within the water.

When combined with a sand filter, some pathogens can become trapped, and ultimately  not survive traversing through the sand. Additionally, certain particulates can be captured from the water in the sand. In this way, large particles can be removed from the water flow.

not survive traversing through the sand. Additionally, certain particulates can be captured from the water in the sand. In this way, large particles can be removed from the water flow.

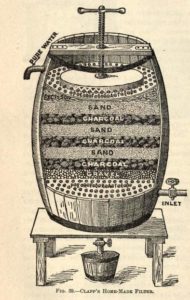

A Clapps HomeMade Filter is an example of the combination of a slow sand filter with biological filtration occurring on the top surface of the sand. A BioSand Filter operates in much the same manner

Even with this success, a filtration process must address particles much smaller. Micropores in cloth or paper seives or ceramic filters will serve. Often, in the wilderness, coffee filters can serve to capture certain levels of particles and pathogens.

The Clapps Filter mentioned above also recommended use of barrels that had been charred on the inside, creating a layer of charcoal on that surface to improve the filtration. One of the earliest examples of charcoal filtration.

More recently, water treatment plants are turning to UV lighting to sterilize water. While effective, it does require the use of energy.

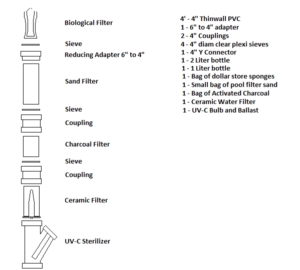

We have constructed a compact five-stage water purification system based on a combination of the above techniques.

We have constructed a compact five-stage water purification system based on a combination of the above techniques.

Water enters the top, flowing over many small sponges where beneficial bacteria await the pathogens. Directly below is the sand filter, again for handling large particulates. The next section adds a charcoal filter, followed by a ceramic micro-pore filter, and finally, we sterilize the water with a UV bulb.

In the diagram at right the general plan is provided. Using PVC pipe, couplings, and seives and acquiring the ceramic/charcoal filter from various survival shops can put one on a good start to build your own system.

The final component, the uv light, is a bit more complicated, but not out of the realm of the handyman.

The final component, the uv light, is a bit more complicated, but not out of the realm of the handyman.